ARNY

Classic | HD | Duplex | Triplex

The counterbalanced truck that wants to reach high.

- Compact design for narrow aisles

- Wide range of applications

- Lifting height up to max. 8.5 m / 278 ft

- Payload up to max. 2.5 t / 5,500 lbs

heavyweight

Versatile heavyweight

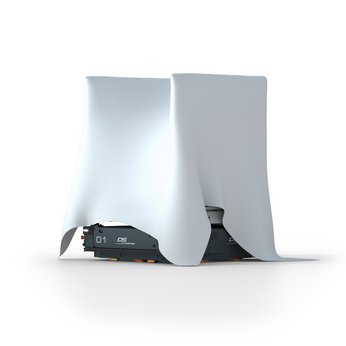

When we developed our ARNY counterbalanced truck, we focused on one central requirement: high load capacity at great heights. But that wasn't enough, we packed its strength into a compact housing so that despite its size it has the necessary flexibility for narrow warehouses.

Driverless counterbalanced truck without compromise

Accessibility

With all our vehicles, we place particular emphasis on ensuring that our components are durable and reliable. But if something does need to be replaced, the vehicle must not be at a standstill for too long. That's why ARNY is designed in such a way that all components can be checked and replaced from a standing start. This minimizes downtimes.

Variability

To ensure that ARNY is not limited to Euro pallets when it comes to picking up loads, we have given it a great deal of variability: The forks can be adapted to a wide variety of loads in different stages. These can be configured for each application via the terminal and the central master control.

PLC safety control

The central heart of the safety system is a Siemens ET200SP F safety PLC, which enables the use and integration of a wide range of certified sensors and actuators via PROFI Safe and I/O Link. In combination with safe radio and vehicle positioning, ARNY can also be integrated into production conditions with increased safety standards.

According to your measurements

When we say ARNY goes high, we mean it. In a variety of designs, it can be used for high-bay warehouses as well as carry unusually large loads.

The best thing about it? With its compact design, it can be integrated into your existing storage system without any problems and is completely geared to your requirements.

The perfect vehicle for your requirements

Shuttle systems

A channel storage system automated by AGV combines the advantages of a high storage density with those of a fully automated warehouse. Here, fork-lift AGVs take over both the storage and retrieval of the pallets and the targeted transfer of the shuttles, if necessary together with their docking station. This means that channel storage systems can be fully automated.

Variants & Technical Data

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/d/csm_DS-Automotion_Thumbails_Arny_proportional_bd8d274af8.png)

Uncompromising industrial suitability combined with a high load capacity and the eye-catching dimension of the lifting height.

- Payload: Max. 1.5 t / 3,300 lbs

- Lifting height: 1,500 mm / 59 in

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/Fahrzeug_Renderings/Arny/DS-Automotion_Thumbails_Arny_proportional.png)

Uncompromising industrial suitability combined with a high load capacity and the eye-catching dimension of the lifting height.

- Payload: Max. 1.5 t / 3,300 lbs

- Lifting height: 4,500mm / 177 in

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/Fahrzeug_Renderings/Arny/DS-Automotion_Thumbails_Arny_proportional.png)

Uncompromising industrial suitability combined with a high load capacity and the eye-catching dimension of the lifting height.

- Payload: Max. 1.5 t / 3,300 lbs

- Lifting height: 8.500mm / 334 in

Uncompromising industrial suitability combined with a high load capacity and the eye-catching dimension of the lifting height.

- Payload: Max. 2,5 t

- Lifting height: 1.500mm / 59 in

Uncompromising industrial suitability combined with a high load capacity and the eye-catching dimension of the lifting height.

- Payload: Max. 2.0t / 4,400 lbs

- Lifting height: 4,500mm / 177 in

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/6/csm_DS-Automotion_Thumbails_Amadeus-Classic_14e5ea0ce9.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/c/csm_DS-Automotion_Thumbails_Lucy_aa27d7de00.png)