PLC technology

Broad PLC technology know-how for our customers

Today, modern PLCs are used for a wide range of tasks.

Simple logic, highly dynamic motion control, innovative safety technology or complex communication tasks can be mapped with them.

Open architecture, industrial suitability, long availability and simple diagnostics are just a few of the advantages that result from the use of PLC controllers in AGV facilities and their environment.

Due to our broad know-how in the field of PLC technology, we can always offer suitable solutions for our customers.

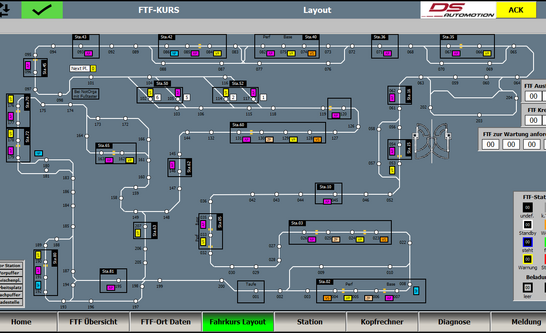

Stationary master control

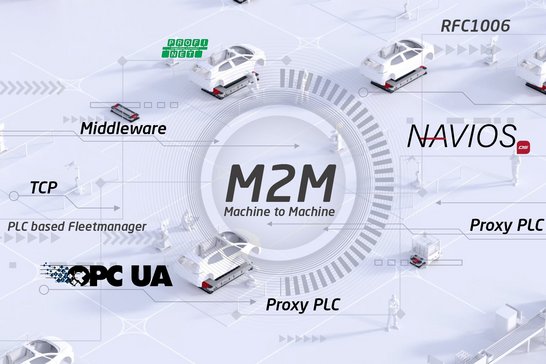

As one of only a few manufacturers, we offer the VDA 5050 interface for PLC-based master controllers and PLC vehicle controllers. We are therefore able to offer all navigation technologies, to expand existing facilities with vehicles or to exchange outdated fleet managers to a DS Automotion master controller.

Today, OPC UA is the preferred technology for M2M communication with AGV facilities, but other technologies such as Profinet, TCP, MQTT or RFC1006 can also be implemented. We support our customers and third-party suppliers in the specification and implementation of the interfaces, for example with requirement specifications, sample projects or complete libraries for TIA Portal, Studio 5000 and other systems.

Our PLC-based control system stands for stability and openness, offers a high degree of flexibility and allows the use of standardized or customer-specific interfaces. It interacts with the AGVs on the one hand and with higher-level customer systems, third-party systems and stations on the other. The master controller is thus the linchpin of the automated guided vehicle (AGV) system. Our customers benefit from the know-how of our experts on Siemens S7 and TIA Portal as well as other manufacturers.

Mobile PLC

Vehicle control

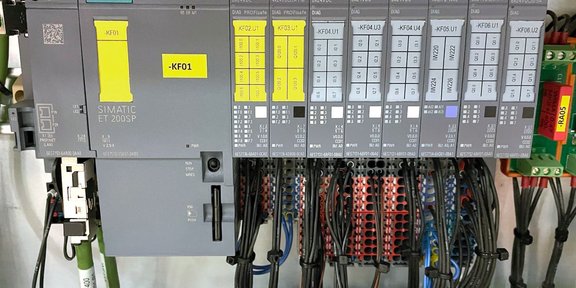

Our track-guided vehicles have a PLC from the Siemens S7-1500 series, which handles all navigation and control tasks and takes care of communication with the master control system. This architecture makes it easy to flexibly adapt the vehicle software to customer requirements.

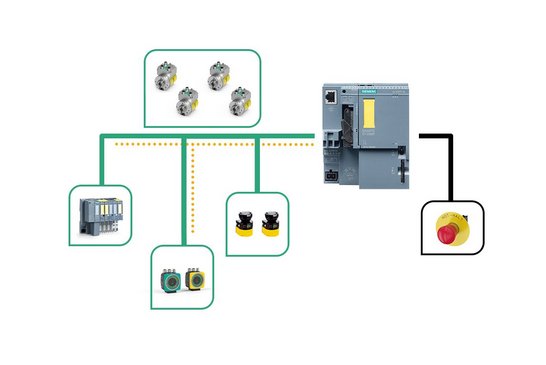

Safety engineering

Programmable safety controllers allow flexible implementation of complex tasks for personnel safety. We are just as much a leader in the use of smart sensors, which are connected via the established standards PROFIsafe, EFI-pro and FailSafe over EtherCAT (FSoE), as we are in the implementation of complex safe motion control applications.

![[Translate to English (Great Britain):] [Translate to English (Great Britain):]](/fileadmin/_processed_/e/1/csm_DS-AUTOMOTION_SPS_abec9e92b9.jpg)

Load bearing

The logic for load handling attachments is programmed in ladder diagram (LD) or function block diagram (FBD). It can be easily and flexibly adapted and diagnosed for each load handling device.