Optimization of the production chain

To ensure that the route between the individual filling stations is also optimally executed, we automate the transport of the silos with our vehicles. Together with our NAVIOS fleet manager, the recipe can be defined, and our vehicles then drive to the stations in the defined sequence and pick up each ingredient with gram precision.

The right vehicle for silo transport

With our AMADEUS wide high lift stacker you have the perfect vehicle to transport silos and containers for filling from station to station. Its extended base enables the silos to be transported in such a way that the lower opening remains free.

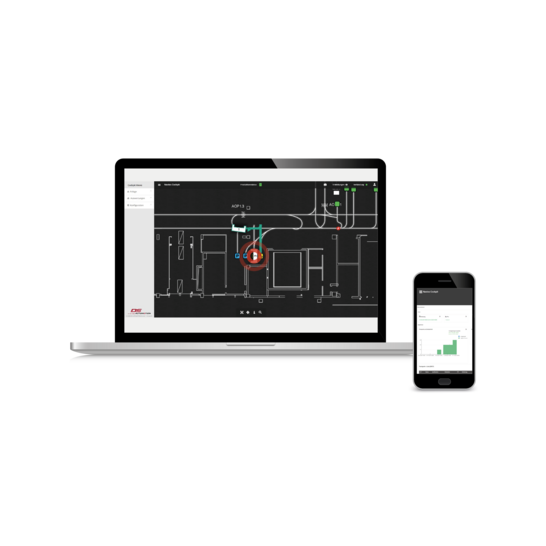

Intelligent software solution

Our NAVIOS software, produced in-house, receives the recipe and, based on it, sends the vehicles to the pick-up stations in the correct order. This way, no mistakes can happen and every ingredient is filled into the silo at the right time and in the right quantity.