The solutions developed by DS Automotion over almost 40 years are as diverse as the requirements for driverless transport systems. The global leader in mobile robotics also actively supports the standardization of communication between mobile robots and the control system with the standardized interface VDA5050. This has been established, but its development is still ongoing. Immediately before publication is a standardized data format for the uniform exchange of driving course information. In addition, there are in-house developments such as navigation with plannable autonomy and communication between vehicles.

Share article

Automated guided vehicles and mobile robotics are developing more dynamically than almost any other area of industrial automation. While only a few suppliers dominated the market up until a few years ago, such vehicles and systems now fill entire halls at trade shows. In addition, suppliers of large, automated warehouse and materials handling systems have integrated them into their own facilities as a flexible addition.

These include classic automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). Some of these can coordinate with each other if necessary and offer more freedom in route selection due to their autonomy. On the other hand, the coordination of vehicles through a central control system brings much more efficiency.

Standardization creates supplier independence

"Customers don't want to be tied to one supplier by proprietary, completely self-contained systems," knows Dipl.-Ing. Lukas Schwarz, Head of Vehicle Basic Software Development at DS Automotion. "They want to have a choice of vehicles so that they can use the optimal device for each individual application."

Therefore, with VDA5050, a standardized interface was created that allows vehicles from different manufacturers to operate under a joint control system and also interact with each other. This enables users to tender the control system and the vehicles separately. For example, they can use standardized control systems for all vehicles, regardless of their manufacturers, thus limiting the effort required for personnel training and software maintenance.

"In addition to an interface description, VDA5050 is a recommendation," specifies the mechatronics graduate engineer, who is helping to drive standardization as a member of the core team of the working group of the German Engineering Federation (VDMA) on VDA 5050. "It represents a platform on which all system and vehicle manufacturers as well as users can build."

Established as standard

The part of VDA5050 that regulates the driving of vehicles is very extensively illustrated. This is not only evident in the mesh-ups that have been carried out annually since 2021, in which vehicles from different manufacturers operate within joint overall systems. "There are already systems with control systems from other manufacturers in which our vehicles run smoothly," reports Lukas Schwarz from the field. " On the other hand, systems with our NAVIOS control system are currently being implemented in which vehicles from other manufacturers will also run."

The standardization process continues

VDA5050 regulates manufacturer-independent, uniform communication between control systems and vehicles. It is therefore now an established standard, compliance with which is explicitly required in tenders. Nevertheless, it still leaves some areas largely open.

One chapter where standardization efforts are still ongoing is the format for the exchange of driving course data. With the Layout Interchange Format (LIF), every AGV master control system should be able to easily import the driving course layout of an AGV system. The VDMA has its own working group for LIF.

"The driving course layout is the responsibility of the vehicle manufacturers," says its leader Christoph Pramberger, M.Sc., specialist team leader development control technology for new projects at DS Automotion. "LIF is about creating a uniform, manufacturer-independent format for mapping a driving course layout." For this purpose, the LIF file contains information about all lanes within an area, such as a hall or a floor, as well as restrictions such as maximum widths or speed limits.

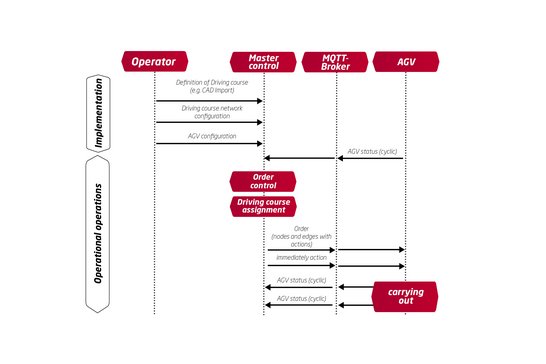

The LIF file is imported from the master control system and extended with additional information to fulfill the master control system tasks, such as traffic control, routing, etc.. Based on this information, communication with the vehicles takes place via VDA5050.

LIF is another important milestone on the way to full interoperability between control systems and vehicles from different manufacturers. LIF is scheduled for release in the second half of 2023.

Load handling and card exchange

Load handling has also been standardized as part of VDA5050. It represents an essential part of the standard, for example, by enabling load transfer between vehicles from different manufacturers. However, only the actions are defined within VDA5050. The actual processes behind this must be defined on a project-specific basis.

Current standardization efforts are focused on the possibility of exchanging maps between vehicles, such as contour maps for localization with laser navigation, natural landmarks, or via specially installed landmarks for precise load transfer.

Planbare Autonomie

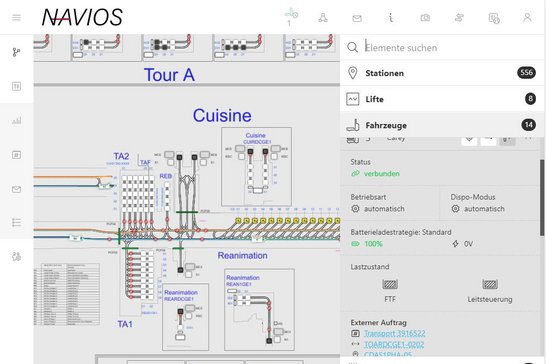

Robots have to work more and more in dynamically changing environments. DS Automotion meets this challenge with the option of defining zones in the NAVIOS control system as an alternative to linear paths, within which autonomously navigating vehicles can find the exact path on their own.

The ARCOS vehicle software not only enables fully autonomous avoidance of unexpected obstacles within user-defined limits, but also the interaction of multiple AMRs in free space. This so-called plannable autonomy thus combines the reliability and efficiency of the centrally controlled system with the flexibility of autonomously navigating vehicles.

DS Automotion received the IFOY AWARD 2023 for this groundbreaking technology.

This is still a unique selling point of the Austrian premium manufacturer, which has been exclusively producing automated guided vehicles (AGVs) and autonomous mobile robotics since 1984.